Description

Dura Aut0-Batch™ Direct Injection Spray Tender System with 3″ Plumbing

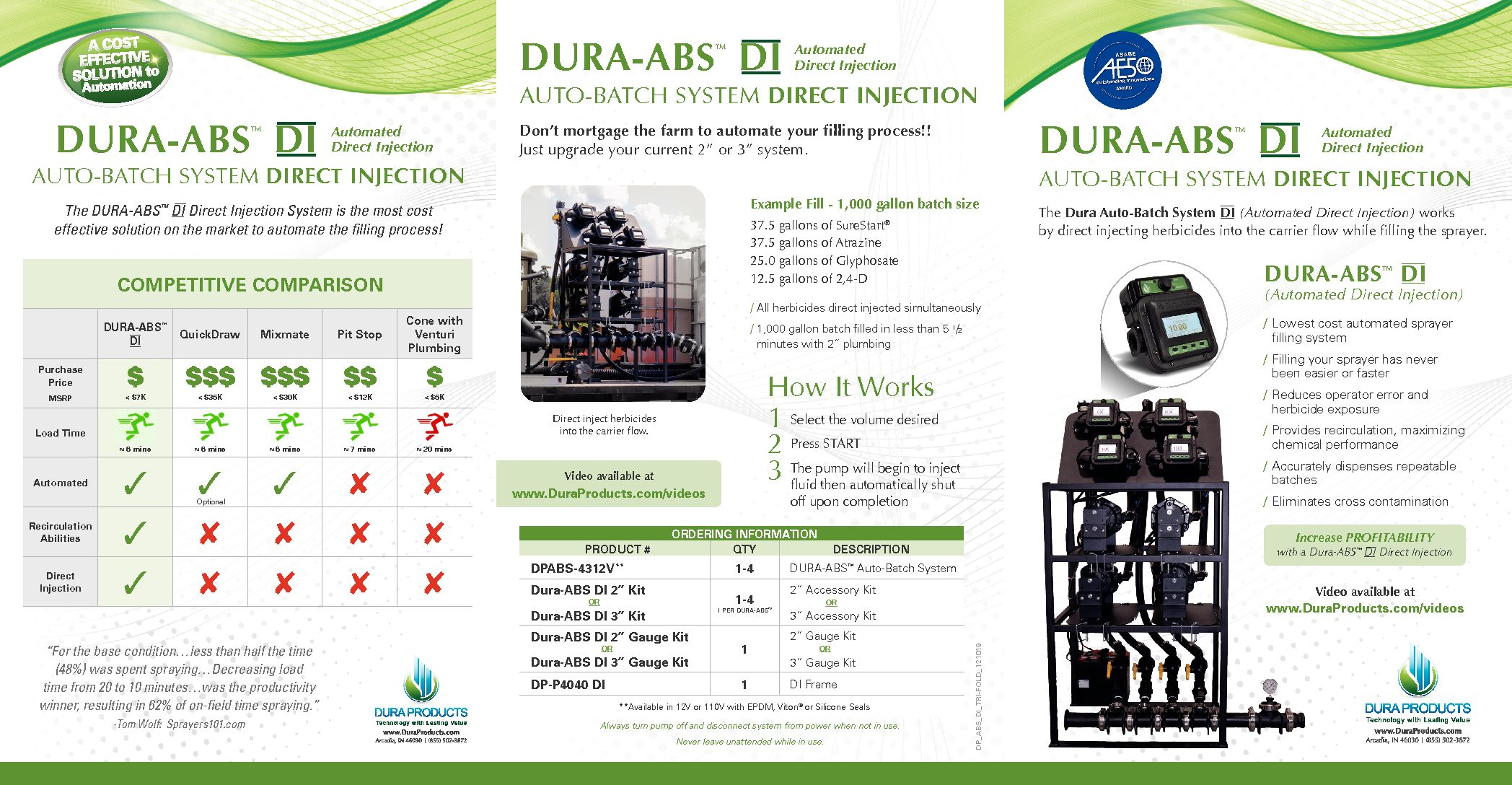

The Dura Auto-Batch™ Direct Injection is an automated spray tender system that works by direct

injecting herbicides into the carrier flow while filling the sprayer

Don’t mortgage the farm to automate your filling process! Just upgrade your current 2″ or 3″ system.

The Dura Aut0-Batch Direct Injection Spray Tender System is the most cost-effective sprayer loading system on the market. This chemical handling system reduces sprayer load time by up to 80%. The system is automated, so the operator can multi-task. It provides recirculation, so it maximizes chemical performance. It simultaneously direct injects chemicals and is a closed fill system, reducing operator exposure to chemicals. The Dura Auto-Batch™ Direct Injection gives you a high return on your investment by maximizing the capacity of your existing equipment and reducing labor and machinery costs.

By optimizing loading efficiency for narrow application windows, you can get a return on your investment in less than 9 spraying days. In fact, the folks over at Sprayers101.com built a model to test the benefits of all of the elements of a spray operation that effect productivity. They found that decreasing sprayer loading time was the winner as far as increasing on-field spraying time. Read the article here.

Calculate your Return on Investment here: https://duraproducts.com/di-direct-injection-roi/

- Lowest cost automated sprayer filling system

- Filling your sprayer has never been easier or faster

- Reduces operator error and herbicide exposure

- Provides recirculation, maximizing chemical performance

- Accurately dispenses repeatable batches

- Eliminates cross contamination

Example fill – 1,000 gallon batch size: Filled in less than 5 1/2 minutes with 2″ plumbing

- 37.5 gallons of SureStart

- 3.75 gallons Atrazine

- 25.0 gallons of Glyphosate

- 12.5 gallons of 2,4-D

How it Works

- Select the volume desired

- Press START

- The pump will begin to inject fluid then automatically shut off upon completion

“Great filling system. Went from 20 minutes load time with two people to less than 7 minutes by myself using the Dura Auto-Batch Direct Injection System. It also allows me to multi-task while filling my sprayer. Takes hours off my machine and keeps me in the field.” – Austin Woodward, Woodward Farm

For more information, visit https://duraproducts.com/dura-abs-di-home/

Call Us for Promotions or Special Configurations! 317-877-7867